Smart Heating Solutions

How to Choose the Right Industrial Heater for Your Needs?

Choosing the right industrial heater can be a daunting task. With numerous options available, making a decision may feel overwhelming. John Miller, a seasoned expert in industrial heating solutions, states, "Selecting the right heater is crucial for efficiency and safety." His insights highlight the importance of understanding different heater types, including electric and gas options.

Understanding your specific heating needs is essential. Consider factors like the size of the area to be heated and the material being processed. Industrial heaters vary widely in capacity, design, and fuel type. A poorly chosen heater can lead to energy inefficiency and operational failures. This choice requires careful thought.

Reflecting on your requirements can help guide you. Don't rush this decision. Take time to evaluate each option. Weigh the benefits and drawbacks of each heater type. Remember, an industrial heater is more than just a piece of equipment—it's a critical component of your operations. A thoughtful selection process sets the foundation for long-term success.

Factors to Consider When Selecting an Industrial Heater

Choosing the right industrial heater requires careful consideration of several factors. First, understand the heating requirements of your environment. According to industry reports, facilities can face energy losses exceeding 30% if heating systems are not adequately matched to the space they serve. It's essential to evaluate the area’s insulation, desired temperature, and operational hours.

Fuel type is another critical aspect. Electric heaters are suitable for small spaces, while gas heaters work best for larger areas. A study indicates that gas heaters can reduce energy costs by up to 15% in specific applications. However, the installation cost and safety measures should not be overlooked. Users might find themselves confused by local regulations concerning emissions and safety standards.

Finally, maintenance needs vary significantly from one heater to another. Regular servicing can extend the life of the equipment but may also add to operational costs. Some users report feeling overwhelmed by these ongoing requirements, which can hamper productivity. Thinking through these factors can help ensure the best fit for heating needs.

How to Choose the Right Industrial Heater for Your Needs?

| Criteria | Description | Examples |

|---|---|---|

| Type of Heater | Identify if you need electric, gas, or infrared heaters based on application. | Electric Wall Heaters, Gas-Fired Unit Heaters |

| Heating Capacity | Determine the desired BTU or watt capacity required for your space. | 10,000 BTU, 25,000 BTU heaters |

| Safety Features | Look for heaters with safety shut-off valves and overheat protection. | Automatic shut-off, Tip-over protection |

| Energy Efficiency | Check for energy ratings to choose a more efficient model. | Heaters with 90%+ efficiency |

| Portability | Decide if you need a stationary or portable heater based on your needs. | Portable space heaters, wheeled heaters |

| Installation Requirements | Consider how much effort and expertise is needed for installation. | Ductless systems, direct vent heaters |

| Maintenance | Evaluate maintenance needs and frequency for keeping the heater operational. | Monthly filter changes, annual service |

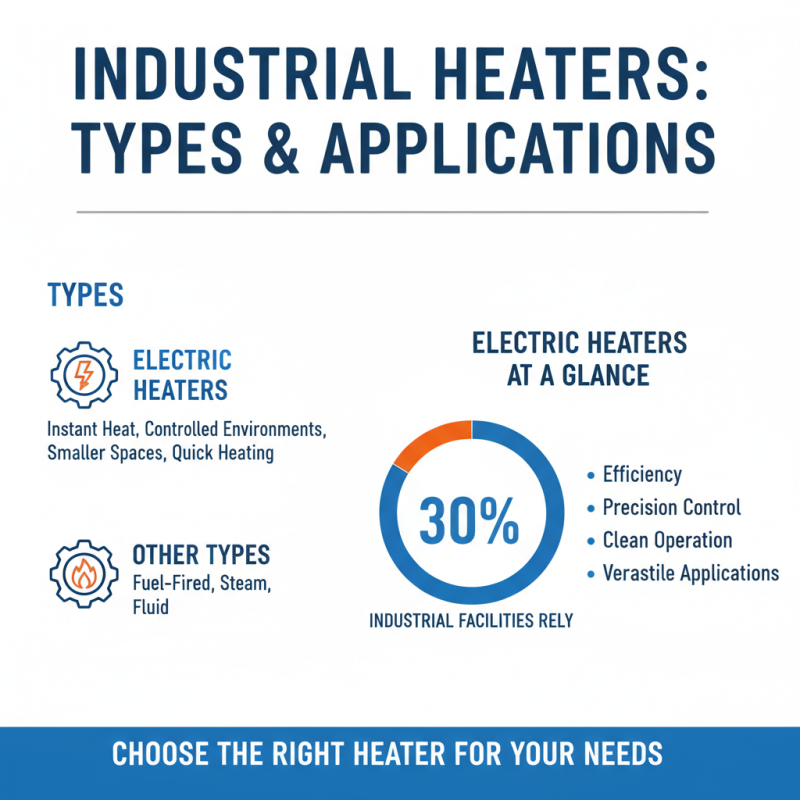

Types of Industrial Heaters and Their Applications

When selecting the right industrial heater, understanding the types available is crucial. There are several heater types, each designed for specific applications. Electric heaters provide instant heat and are often used in controlled environments. They are ideal for smaller spaces and quick heating tasks. According to industry reports, about 30% of industrial facilities rely on electric heaters due to their efficiency.

Gas heaters, on the other hand, are used for larger spaces. They burn natural gas or propane. This type is effective for outdoor settings or warehouses. However, ensure proper ventilation to avoid hazardous gas buildup. Many industries prefer gas heaters for their lower operational costs. Statistics show that gas heaters can cut heating costs by up to 50%.

**Tip:** Assess your heating requirements before making a decision. Knowing the space size and required temperature helps in choosing the right heater.

Radiant heaters offer targeted heating by warming surfaces instead of the air. This can be a more energy-efficient option. They are especially useful in factories with open layouts. However, radiant heaters may not be suitable for every environment. Their efficiency can diminish in areas with high ceilings or drafts.

**Tip:** Always consult an expert for a site evaluation. An experienced technician will identify potential inefficiencies in your heating setup and suggest improvements.

Assessing Heating Requirements for Your Specific Industry

Choosing the right industrial heater requires careful assessment of your heating needs. Different industries have unique requirements. For example, a food processing plant needs precise temperature control. Meanwhile, a warehouse may prioritize uniform heating to prevent damage to stored goods.

Tips: Evaluate the space. Measure the area that requires heating. Know the height of the ceilings. This helps in calculating the required heater output. Consider insulation levels. Poor insulation increases heating demands.

Understand the materials you'll be working with. Some processes generate heat naturally. This might reduce the need for additional heating. However, don’t underestimate the fluctuations in temperature. Unforeseen changes can affect product quality. Regular maintenance and monitoring of temperature can prevent problems.

Tips: Consult with your team. Gather insights from those who work directly with heating equipment. They might offer valuable practical knowledge. Compare different heater types. Each has its pros and cons depending on the specific industrial application. Consider long-term energy costs. This influences the overall budget.

Choosing the Right Industrial Heater for Your Needs

This bar chart illustrates the heating requirements in BTU/hr for different industries. Understanding these needs is crucial for selecting the appropriate industrial heater to maximize efficiency and comfort in your specific application.

Energy Efficiency and Cost-Effectiveness in Industrial Heating

When selecting an industrial heater, energy efficiency and cost-effectiveness are paramount. According to a report by the U.S. Department of Energy, industrial heating accounts for 29% of total energy consumption. Thus, choosing the right heater can significantly impact operational costs. A well-selected heater can reduce energy bills by as much as 35%. This is not just savings; it’s crucial for sustainability in manufacturing processes.

Tips: Consider heaters with variable output controls. This feature allows adjustments based on demand. This flexibility improves efficiency and reduces excess energy use.

Investing in high-efficiency heaters, such as those with advanced insulation or energy recovery systems, can yield long-term benefits. A study from the Institute of Energy Technology shows that these systems often recoup their initial costs within two years. Yet, businesses must remain cautious. High upfront costs might deter some, though the long-term gains outweigh initial investments.

Tips: Evaluate total cost of ownership, not just purchase price. Look beyond the initial expense. Factor in maintenance, operation, and efficiency gains over time. This holistic view often leads to more informed decisions.

Safety Features and Compliance Standards for Industrial Heaters

When choosing an industrial heater, safety features are paramount. According to industry reports, approximately 30% of industrial accidents are related to equipment malfunction. Reliable heaters should include automatic shut-off features and temperature controls. These systems prevent overheating and potential fire hazards.

Compliance with safety standards is also crucial. In the United States, heaters must meet OSHA and ANSI requirements. These organizations mandate specific design features to minimize risks. For instance, thermal cutoffs are common. They shut off power during dangerous temperature spikes. Equipment that fails to meet regulations can be hazardous.

User training plays a significant role in safety. Many operators underestimate the importance of proper handling. Nearly 40% of workplace accidents arise from inadequate training or oversight. Regular safety audits can mitigate these risks. Involving staff in compliance discussions fosters a culture of safety. Understanding equipment limitations is essential for safe operation.

Related Posts

-

Why You Should Choose a Portable Electric Heater for Your Winter Comfort

-

Top 10 Benefits of Wall Mounted Electric Heaters for Home Heating Solutions?

-

Top 10 Commercial Electric Heaters: Efficient Heating Solutions for Your Business

-

Top 2025 Line Voltage Thermostat Features You Need to Know

-

Top 10 Wall Mounted Heaters for Efficient Home Heating Solutions

-

10 Essential Tips for Choosing the Best Portable Electric Heater