Smart Heating Solutions

What is a laboratory sample pulverizer and how does it work?

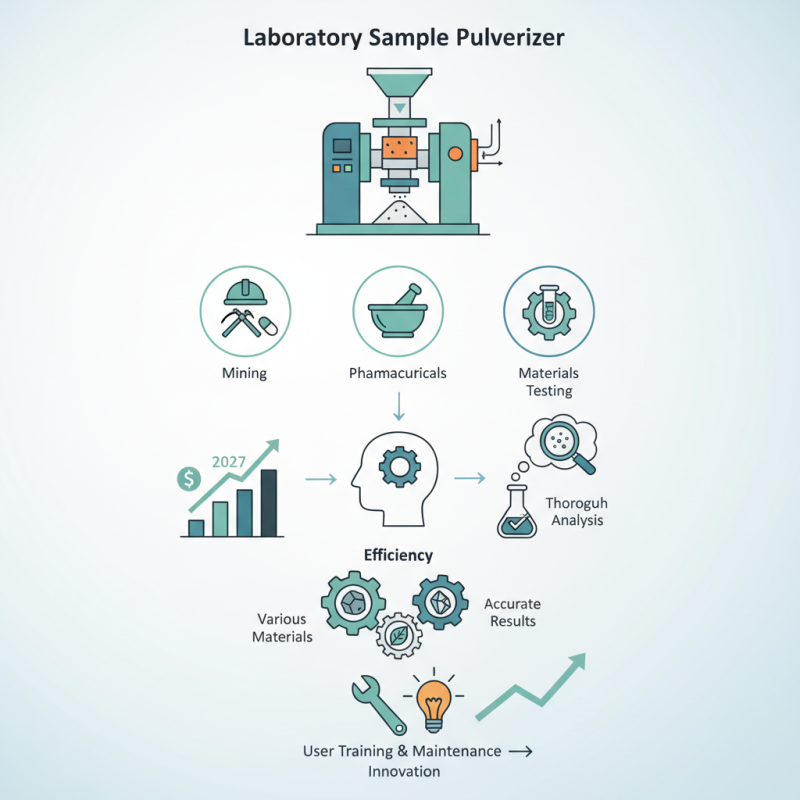

laboratory sample pulverizers play a crucial role in numerous industries, including mining, pharmaceuticals, and materials testing. According to a recent report from Market Research Future, the laboratory equipment market is projected to reach $45 billion by 2027, with sample pulverizers being a significant segment. These devices are essential for crushing solid materials into a fine powder, allowing for thorough analyses.

Dr. Emily Johnson, a leading expert in material science, states, "The efficiency of a laboratory sample pulverizer directly influences the accuracy of test results." This underscores the importance of selecting the right pulverizer to achieve precise sample preparation. The laboratory sample pulverizer's design allows it to handle various materials, from minerals to organic compounds, yet challenges remain.

Despite advancements, some users struggle with understanding operational limits. Overusing a pulverizer can lead to contamination or compromised sample quality. This challenge highlights the need for user training and equipment maintenance. With a focus on precision and efficiency, laboratory sample pulverizers continue to evolve, driving innovation in sample preparation methodologies.

What is a Laboratory Sample Pulverizer?

A laboratory sample pulverizer is a >vital tool in many research and industrial settings. It is specifically designed to grind materials into fine powders for analysis. The mechanism is fairly straightforward yet effective, making it ideal for various samples. These machines often use blades or plates to crush samples rapidly. The process creates a homogenous powder, which is crucial for reliable testing.

Laboratory sample pulverizers work by applying mechanical force. The input material is placed into a chamber, where it is subjected to intense pressure. As the blades or plates move, they break down the sample into smaller particles. The size of the output can be adjusted depending on the material and intended use. Users must be cautious in this aspect; achieving the desired particle size can sometimes be challenging.

Storage and maintenance are important considerations for these instruments. Regular cleaning ensures that no cross-contamination occurs between different samples. Additionally, research shows that occasionally, the blades may wear out, affecting performance. It is essential to monitor their condition. Incomplete grinding can lead to inaccurate results, affecting the overall quality of research. These details may seem minor, but they significantly impact the final outcomes.

Key Components of a Laboratory Sample Pulverizer

A laboratory sample pulverizer is a key tool used in material analysis. It breaks down samples into finer particles for testing. The design focuses on efficiency and accuracy. Let's explore the key components that make this device effective.

The grinding chamber is essential. It houses the sample and lets it be crushed. The power source drives the process, generating necessary speed. The blades inside are sharp and sturdy. They create a high-impact crushing action. A well-designed chamber ensures uniform particle size. This is crucial for reliable results.

Tips: Always clean the chamber after each use. Residual materials can affect future samples. Proper maintenance of the blades is also important. Dull blades lead to inconsistent grinding results.

Another vital component is the sample feed. It controls how the material enters the chamber. An uneven feed can lead to jams or poor grinding efficiency. Regular checks on the feed mechanism help prevent such issues. Identify signs of wear and replace parts promptly.

In your workflow, always consider the amount of sample you input. Too much can overwhelm the pulverizer. This may result in slower processing and inadequate grinding. Adjust these variables based on your material’s characteristics. Proper calibration ensures optimal performance.

Understanding the Pulverization Process and Mechanics

A laboratory sample pulverizer is an essential tool in material testing and analysis. It reduces materials into fine particles, facilitating accurate testing and analysis. The pulverization process involves various mechanical actions, primarily impacting, grinding, and shearing. These actions allow materials like minerals, chemicals, and soil to be processed efficiently.

Understanding the mechanics of pulverization reveals its importance in multiple industries. According to recent industry reports, nearly 60% of laboratory samples require some form of size reduction. This step is critical for achieving uniformity in particle size, which enhances the reliability of subsequent tests. Materials are subjected to powerful forces as they are ground down, often resulting in a notable change in texture and consistency.

Tips: Always ensure that the sample size is appropriate for the pulverizer used. Oversized samples can hinder performance. Additionally, regular maintenance of the pulverizer is crucial to minimize contamination. Consider calibrating your device to ensure precision and accuracy in the results. Regular checks can prevent operational flaws.

Applications of Laboratory Sample Pulverizers in Various Industries

Laboratory sample pulverizers play a vital role in various industries. They reduce materials to fine powders for testing and analysis. In the mining sector, these machines are essential for preparing ore samples. According to a recent industry report, the global mining equipment market is projected to reach $163 billion by 2025. This growth highlights the increasing reliance on efficient sample preparation.

In the pharmaceutical field, accuracy is crucial. High-quality pulverizers ensure consistent particle size for drug formulations. This can impact bioavailability and efficacy. The pharmaceutical industry is also expected to grow, reaching over $1.5 trillion by 2023. Efficient sample processing will be a key factor in meeting this demand.

However, the use of laboratory sample pulverizers is not without challenges. Sometimes, operators may overlook calibration, leading to inaccuracies. Regular maintenance is necessary, but it can be costly and time-consuming. Industries must balance operational efficiency with the need for precision. These nuances reflect the importance of continuous improvement and training in sample preparation techniques.

Data on Particle Size Reduction and Efficiency in Sample Pulverizers

A laboratory sample pulverizer is a critical tool in material analysis. This device is designed for particle size reduction. It transforms bulk materials into finely powdered samples for testing. Understanding how it works can improve efficiency in laboratories.

Data show that the efficiency of sample pulverizers varies. Factors such as sample hardness and desired particle size play significant roles. A softer material reduces time and energy needed for processing. However, too soft may lead to inconsistent results. The ideal situation typically balances between the type of material and the desired outcome.

Tips: Regular maintenance is crucial. Clean the pulverizer after every use to prevent contamination. Also, check for wear on grinding elements. Always calibrate the machine for accurate measurements. These small steps can significantly enhance your sample quality.